337-508-0950

Spartan-Grade Epoxy Floors Built to Last

Premium epoxy flooring for garages and workspaces in Lake Charles.

Clean finishes. Tough coatings. Honest pricing.

The Starting Point

Every epoxy floor starts with what’s already there—and in this case, it was raw, worn concrete that had seen years of use. Oil stains, discoloration, and surface wear are common in working shops like this. Before anything gets coated, we assess the slab, the traffic it sees, and what needs to be corrected to make the floor both durable and good-looking.

Surface Preparation

Proper prep is what makes an epoxy floor last. We mechanically grind the concrete to remove the top layer, exposing a clean, porous surface that allows the epoxy to bond correctly. After grinding, we check moisture levels in the slab to make sure the coating system we use won’t fail over time. This step is where durability is earned, not rushed.

Crack Repair & Final Prep

After grinding and moisture testing, we chase and repair cracks using a concrete bonding compound to prevent future cracking or seepage. Those repaired areas are then re-ground to keep the surface flat and uniform. If the slab has low spots, we apply self-leveler where needed to correct them. Once everything is repaired, the floor is thoroughly cleaned and allowed to fully dry before any coating is applied.

Epoxy Application

Epoxy installation is a multi-step process that’s customized to the condition of the concrete and the customer’s goals. Depending on the system, we start with a base coat and allow it to cure based on its specific requirements before applying the Part A/B epoxy layer. Decorative flakes are broadcast immediately for texture and coverage, then scraped once cured to remove loose material. Additional coats and flakes are added as needed, followed by a final topcoat with a non-slip additive to create a durable, glossy finish built to last.

Man Behind the Helmet?

My name is Terrell Istre, born and raised in Lake Charles, Louisiana, where reputation matters and you treat people like neighbors. I got into epoxy flooring after seeing a so-called “professional” company come in from out of town, charge a local business owner an outrageous price, and leave him with a terrible finished product. That didn’t sit right with me. I’ve been working with concrete and floors for over 8 years, and when epoxy started gaining traction in both residential and commercial spaces, I saw the potential immediately. I decided to start laying epoxy floors for folks right here in South Louisiana—homes and businesses alike—with honesty, fair pricing, and pride in the work. My goal is simple: give your space a facelift, increase its value, and leave you genuinely happy with the result.

Call Us Now: 337-508-0950

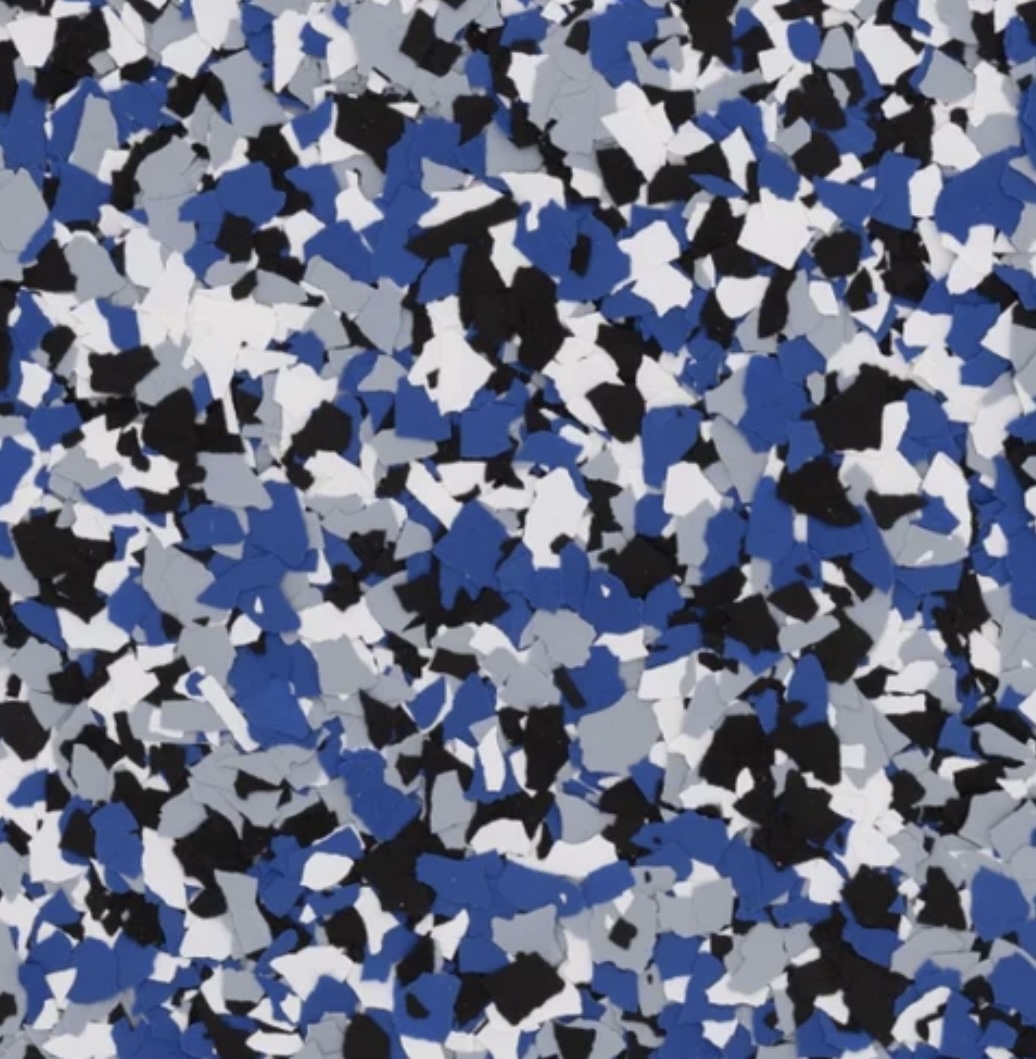

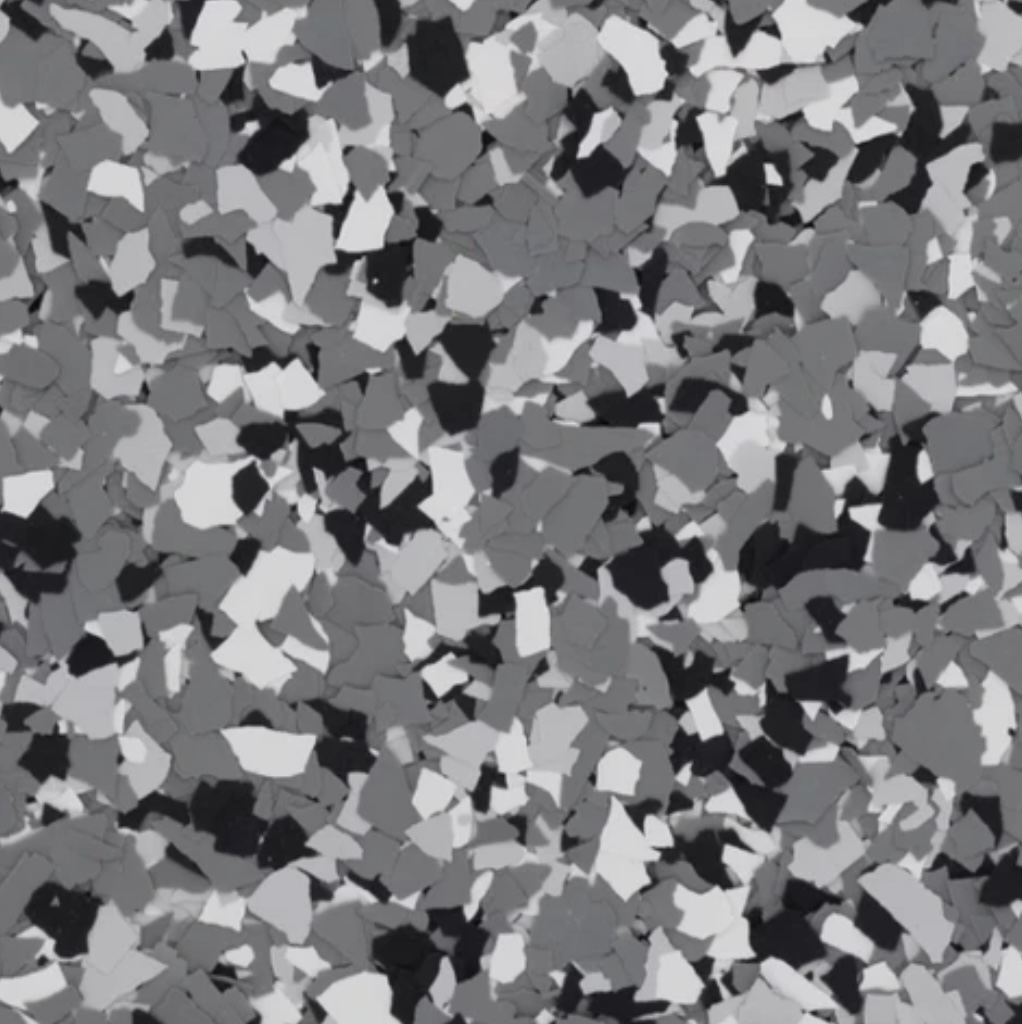

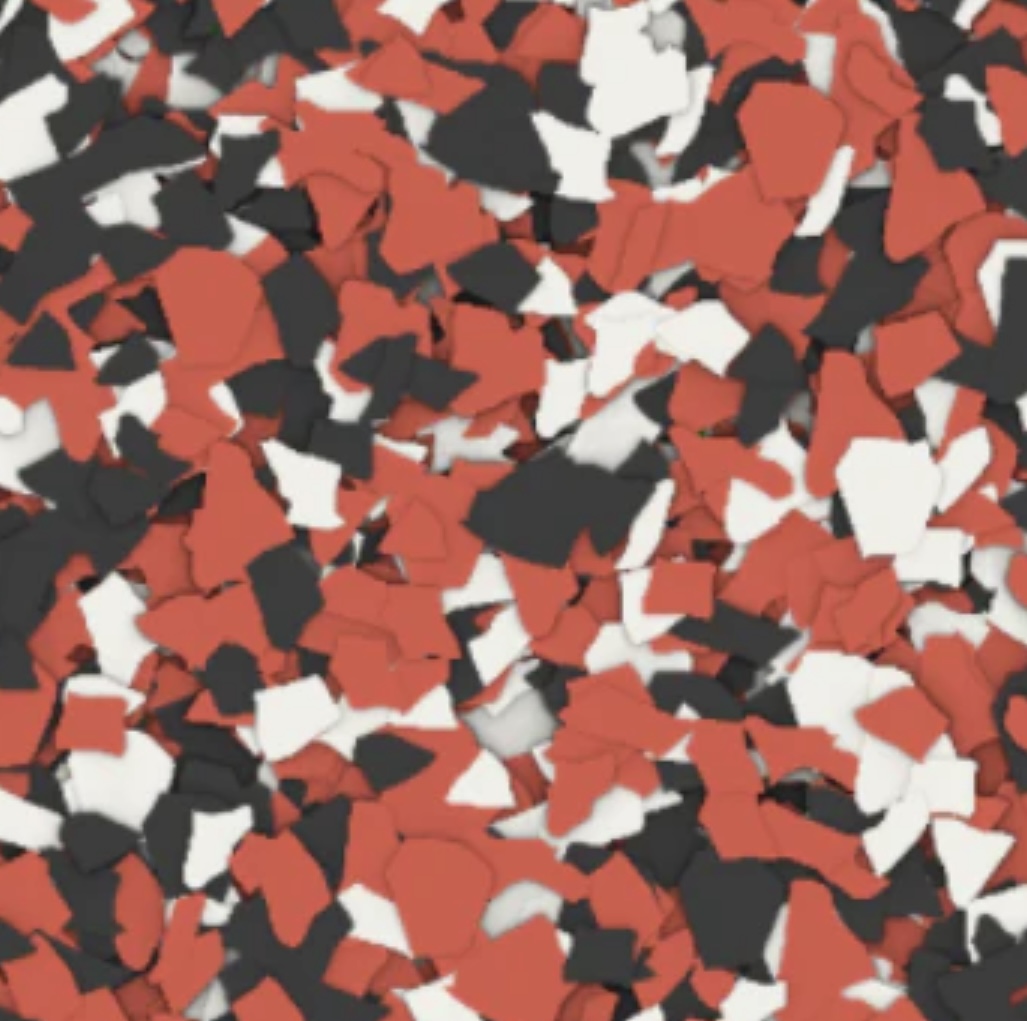

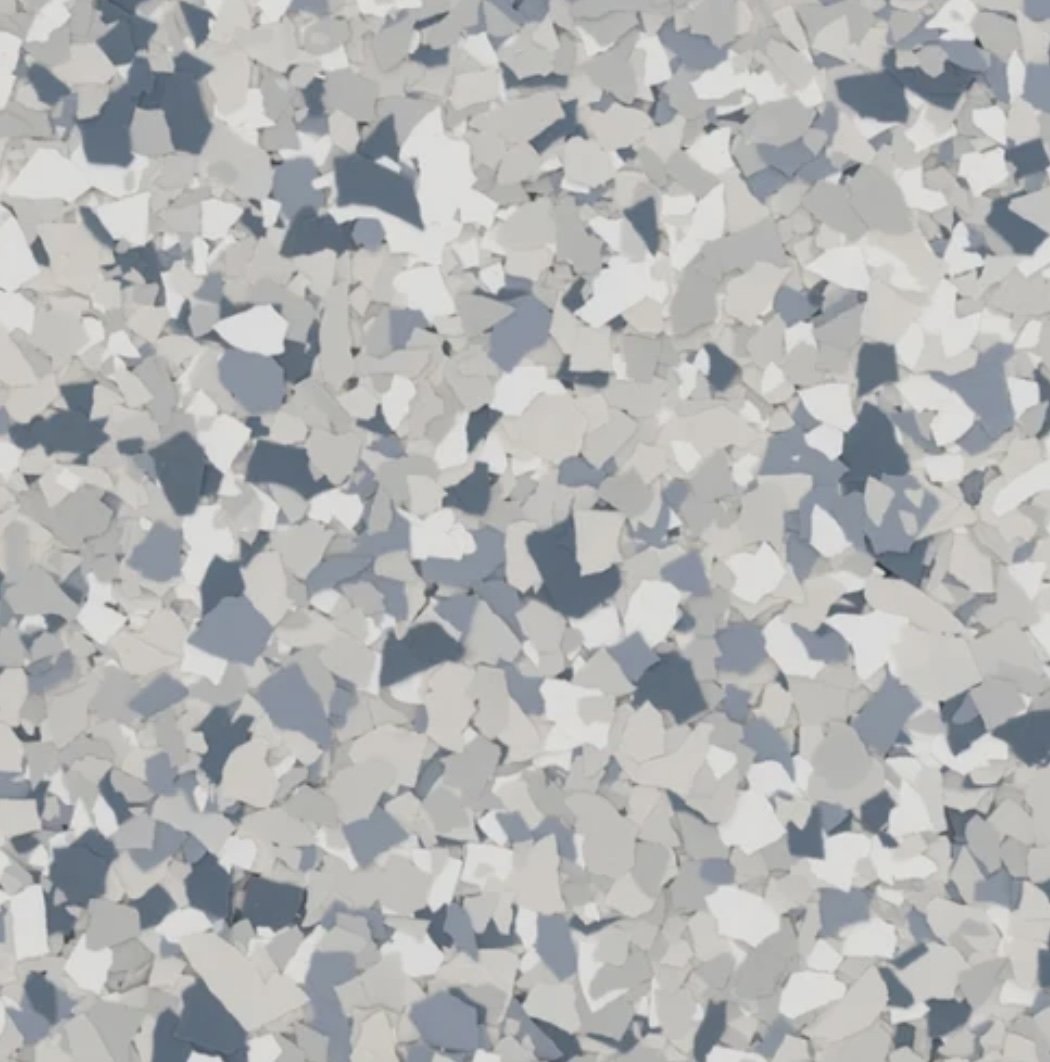

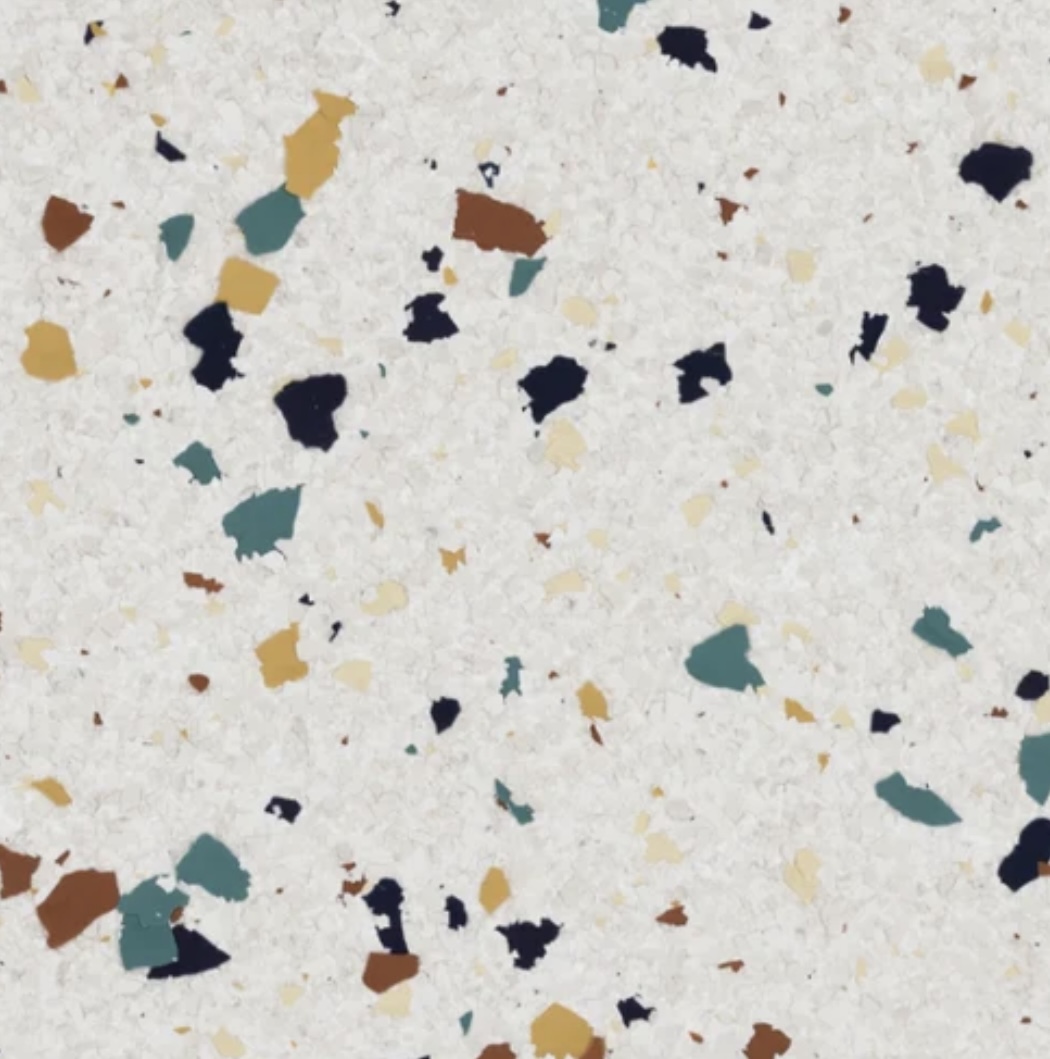

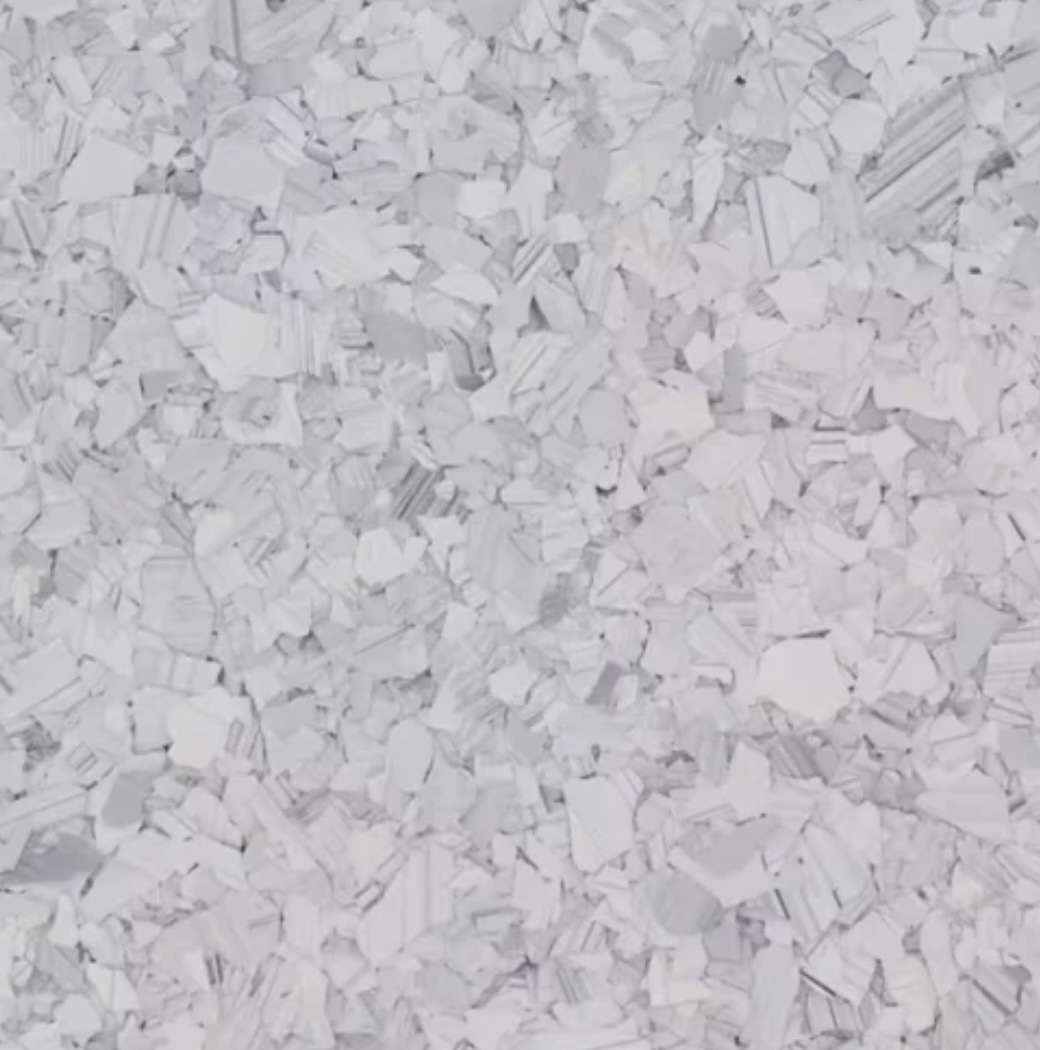

Explore Our Signature Flake Options

Blue/Black

Grey/Black

Red/Black

LSU

Dessert

Ocean

Colored Hybrid

Mixed Hybrid

Spartan Black

White Hybrid

Grey Hybrid

Brown Hybrid

FAQs

Your Questions Answered:

How long does an epoxy floor installation take?

Most epoxy floors take 2–3 days from start to finish, depending on the condition of the concrete and the system you choose. Proper prep, curing time, and multiple coats are critical for long-term performance. We don’t rush installs because cutting corners leads to failures down the road.

How much does epoxy flooring cost?

Pricing varies based on square footage, concrete condition, and the type of system installed. That said, we offer the best prices around and will beat any local competitor’s quote for the same scope of work. You’ll always get clear pricing and no surprises.

Why should I choose a local epoxy contractor instead of a big company from out of town?

We’re local to Lake Charles, and reputation matters here. We treat every customer like a neighbor because that’s exactly what you are. Unlike out-of-town crews, we’re here before, during, and long after the job is done.

What kind of warranty do you offer?

We stand behind our work with a 5-year no-peel warranty and a satisfaction guarantee. If something isn’t right, we make it right. Simple as that.

Is epoxy flooring durable enough for garages and workspaces?

Yes — when it’s installed correctly. We specialize in garages and workspaces, and our systems are designed to handle vehicle traffic, tools, equipment, and daily wear. Prep and proper materials make all the difference, and that’s where our experience shows.

Do you offer alternatives to epoxy flooring?

Absolutely. If epoxy isn’t the best fit for your space, we also install polyaspartic and quartz systems. We’ll walk you through each option during your consultation — including design input — so you end up with the best-looking and longest-lasting floor for your needs.